Description

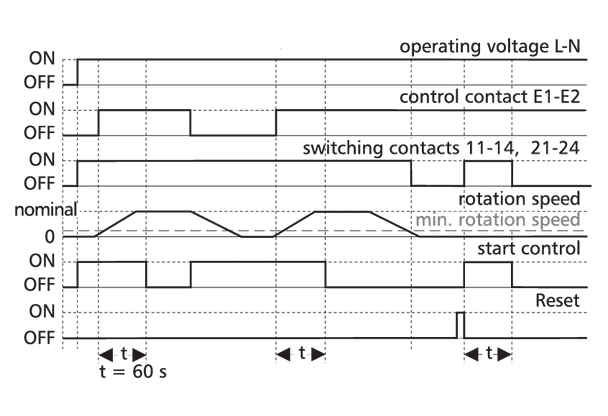

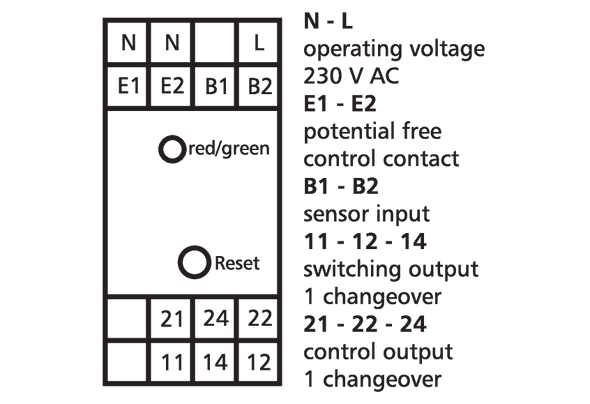

The speed and V-belt monitor is used for monitoring the rotary movement (insufficient speed) of motor and V-belt driven shafts. Inductive proximity switches are used for capturing the speed. Pulses are generated by the sensor without contact by means of driven control cams, toothed wheels, segmented discs, metal signal flags or similar. The relay is activated when the operating voltage is applied. After start-up bridging has finished, the monitoring function is started on the E1 and E2 terminals by means of the power contactor of the drive. When the drive speed falls below the switch-off speed, the relay is deactivated. The fault message of the speed or V-belt monitor is reset by means of the reset function und by switching off the operating voltage.

Resources

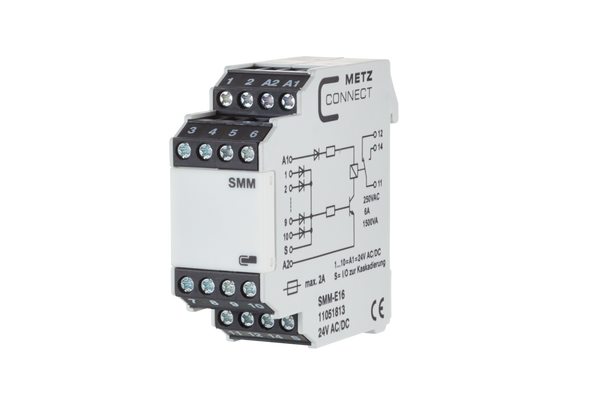

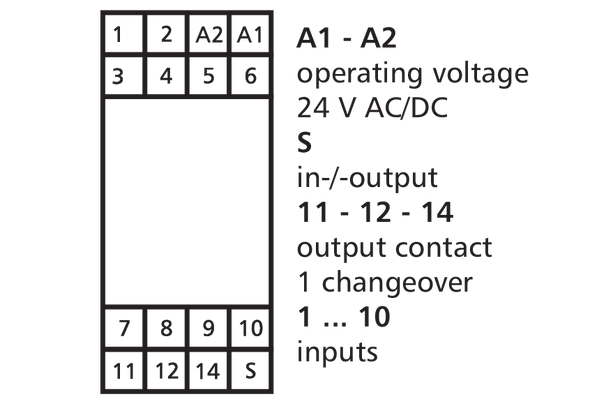

| DRIW-E16, 24 V AC/DC | 1101501322 | View DataSheet |

|---|