Description

For assistance, email CustomerService@americancableassemblies.com or call (413) 283-2515 (8AM - 5PM ET).

American Cable Assemblies takes pride in the creation of our Custom Pre-Terminated Fiber Optic Cable Assemblies, meticulously crafted in the USA with a distinguished legacy of 25+ years marked by unparalleled premium quality and reliability. As an ISO 9001 certified manufacturer, we uphold stringent quality control processes, ensuring excellence at every stage.

Experience the simplicity of our ordering process, coupled with the swiftest production and transit times in the industry. We provide continuous updates on your order status, delivering instant order confirmations, a ship date within 24 hours, and tracking information as soon as your custom assembly is dispatched.

Upon receiving your custom order, we meticulously construct the assembly to your precise specifications, utilizing premium components, including Corning® glass. Skilled technicians in the USA oversee the assembly process with rigorous quality control measures, presenting you with a fully tested product ready for immediate installation. Rest assured, your fiber assembly will not only arrive promptly but will also surpass your expectations. Our knowledgeable experts are available to assist you in selecting the ideal assembly for your specific application.

Tailored for various scenarios, our pre-terminated fiber optic assemblies are ideal for headend termination to a fiber backbone, terminating fiber rack systems, multi-floor deployments, and intra-building backbones. Additionally, our indoor plenum-rated jacket assemblies are suitable for all indoor installations, including plenum-rated spaces, meeting the low-smoke characteristics defined by the NFPA (National Fire Protection Agency).

American Cable Assemblies Indoor/Outdoor Plenum Rated Interlocking Armored Fiber Optic Cable Applications:

Our Pre-Terminated Fiber Optic Cable Assemblies, featuring an Indoor/Outdoor Plenum Rated Interlocking Armored Jacket, offer a cost-effective solution for applications requiring innerduct or conduit, ensuring superior crush resistance and versatility. This option eliminates the 50-foot fire code requirement for outdoor cables, making it suitable for various indoor and outdoor installations. The interlocking armored design ensures durability, making it ideal for environments with rodent hazards. These pre-terminated fiber optic assemblies are perfect for headend termination, fiber rack systems, multi-floor deployments, and intra-building backbones, meeting plenum installation standards.

American Cable Assemblies Manufacturing Features:

- Each strand features 2-millimeter color-coded or sequentially labeled furcation tubing, ensuring easy identification and added durability throughout the entire installation process.

- The transition from the jacket to the furcation tubing is reinforced with heat shrink tubing and glue, providing superior strength and strain relief, guaranteeing resilience during the pull.

- Connectors inside the basket are staggered to reduce bulk and enhance flexibility for a smoother installation experience.

- Individual plastic wrapping of each connector prevents contamination by pulling lubricants or other contaminants, ensuring optimal performance.

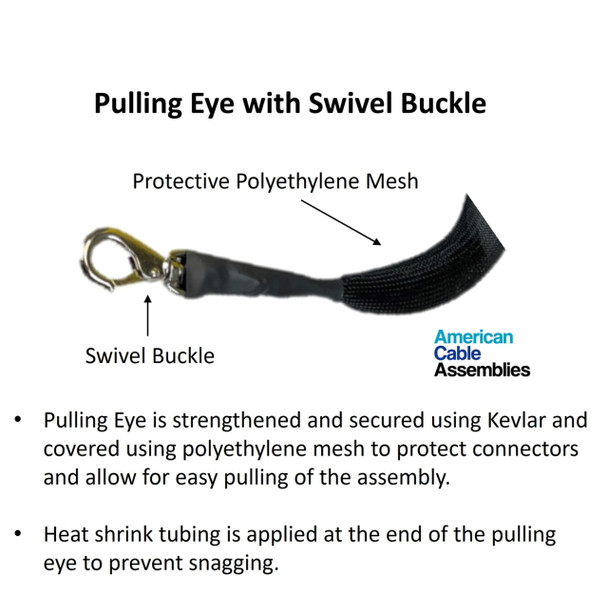

- Pulling Eyes (pulling baskets) are constructed from super-strong polyethylene mesh and feature a free-spinning buckle to prevent twisting during cable pulls. Heat shrink tubing is strategically applied:

- At the basket's connection with the turnbuckle (pull eye hook).

- Where the basket ends and connects with the cable jacket to prevent snags and ensure a seamless pull.

- Every assembly includes a wrap-around label on both ends, featuring the American Cable Assemblies part number and a unique serial number for comprehensive identification.

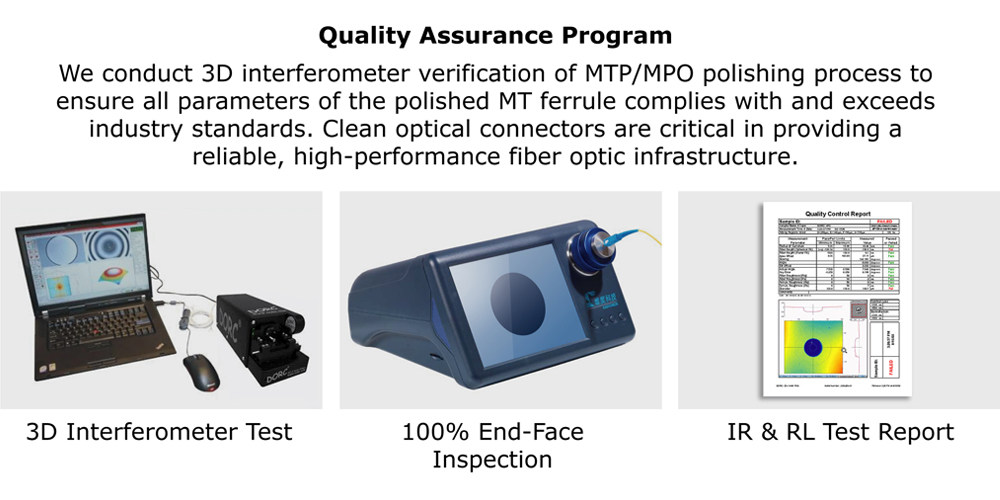

- A complete test report is included with each assembly, featuring a visual inspection of all fiber ends using a fiberscope of 400 power or better. This meticulous examination checks for surface defects like cracking, pitting, and scratches on the glass surface of the connector. Furthermore, all connector ends undergo testing with a professional-grade Loss Test Set.

- Test reports are securely stored in our database for one year and can be requested at any time, providing a transparent record of the assembly's quality.

- Assemblies exceeding 100ft are conveniently placed on a spool for easy installation, while those under 100ft are neatly air-spooled for efficiency.

- Swift Custom ISO 9001 Certified Production in the USA.

American Cable Assemblies Manufacturing Features and Characteristics:

- Manufactured in the USA and certified with ISO 9001.

- High-performance bandwidth: 2000MHz.km@850nm.

- Available in Riser Rated (OFNR) or Plenum (OFNP) Rated with PVC Flame Retardant properties.

- Minimum Bend Radius (Installation): 2&4 Strand – 6.6cm, 6 Strand – 7.2cm, 8-12 Strand – 8.7cm, 18 – 24 Strand – 11.7cm.

- UV Rated Distribution Jacket for enhanced durability.

- Minimum Bend Radius (Operation): 2&4 Strand – 4.4cm, 6 Strand – 4.8cm, 8-12 Strand – 5.8cm, 18 – 24 Strand – 7.8cm.

- Wavelength: 850/1300nm.

- Aramid Yarn Strength Reinforcement Inside Jacket for effective water blocking.

- Outer Diameter: 2&4 Strand – 4.4mm, 6 Strand – 4.8mm, 8-12 Strand – 5.8mm, 18 – 24 Strand – 7.8mm.

- Link Length: 300 meters (10Gb/s@850nm).

- Heavy-duty distribution jacket provides robust protection during installation and in rugged use applications.

- Multimode OM3 50/125 ClearCurve Fiber, exclusively utilizing Corning® Optical Fibers.

- Available Jacket Colors: Black.

- All component materials meet EU RoHS and REACH Directive standards.

- Temperature Range: Storage -40ºC to +70ºC, Operation -40ºC to +70ºC.

- 900 µm Tight Buffers for enhanced performance.

- Jacket print ensures easy product identification and fiber type recognition.