Description

2 Strand OCC DX Series 900 µm Tight Buffered, Indoor/Outdoor Distribution, OFNR Riser, Multimode 62.5/125

Reference Previous Part Number:BX08-085K-ALS/900-OFNP

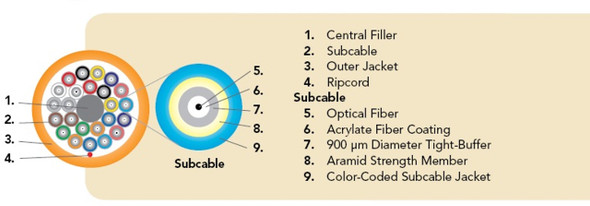

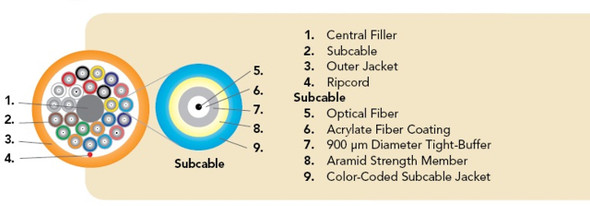

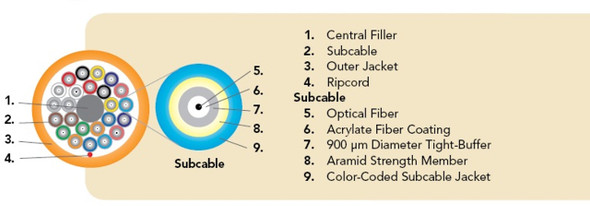

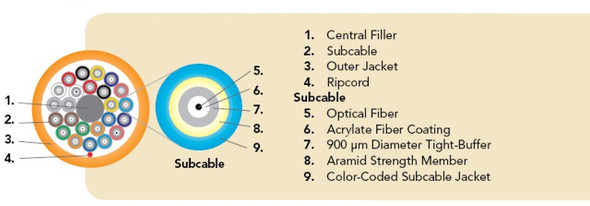

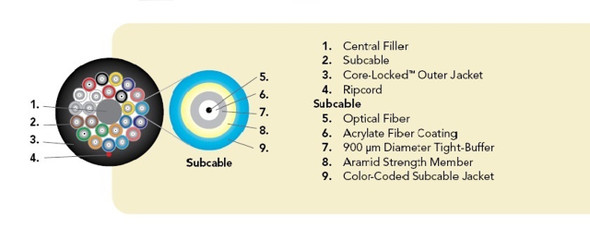

Note: This item may require 24 hours for cut and prep before shipping.Cable Charecteristics: B-Series Breakout Plenum Cables (with 2.0mm subcables)

| Tensile Load | Menimum Bend Radius | ||||||

| Diameter | Weight | Installation | Operational | Installation | Long Term | ||

| Fiber Count | Part Number | mm/(in) | kg/km (lbs/1,000) | N (lbs) | N (lbs) | cm (in) | cm (in) |

| 8 | BX008KALS9OP | 8.7 / (0.34) | 88 / (59) | 3200 / (720) | 800 / (180) | 13.1 / (5.2) | 13.1 / (5.2) |

Applications:

- Ideal for installations requiring an extremely rugged and reliable cable design where maximum mechanical and environmental protection are required

- Installed in ducts, plenums, and air handling spaces

- Easiest cable to install where direct termination of connectors to sub-units and direct run to panels and equipment is desired

Features:

- High performance components and construction

- UL Listed in accordance with NEC sections 770.179(a) for use in ducts, plenums and air-handling spaces

- Most rugged and easy to install cable design for enterprise cabling applications

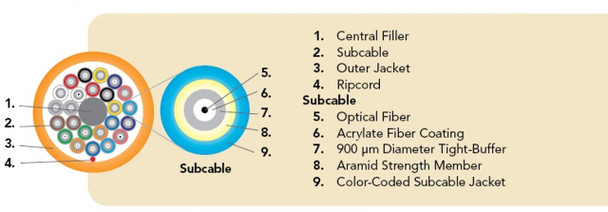

- Standard 2.0mm subcables can be directly terminated with standard connectors. 2.5mm and 2.9mm subcable sizes are also available

- Subcabled fiber is environmentally and mechanically protected

- Ideal for use in point-to-point runs in adverse environments

- Direct termination to subcable provides additional strain relief for better connector retention during moves, adds, and changes

- Design is ideal for direct pulling with mesh grips

- Cable materials are Indoor/Outdoor - UV, water and fungus resistant

- Wide operating temperature range of -40°C to +85°C

- High performance 900 micron tight buffered coating on each optical fiber for environmental and mechanical protection

- Jacket highly chemical resistant for installation in harsh industrial environments

- Interlocking armor can be applied to cables as an alternative to conduit installation

- 2 to 60 fibers

Cost Savings:

- Direct termination to subcable may eliminate the need for patch panels and patch cords and reduce connector loss

- 900 µm eliminates the need for costly and time-consuming installation of fanout kits or pigtail splices because connectors terminate directly to the fiber

- High crush resistance may eliminate the need for innerduct

Mechanical and Environmental Performance

| Indoor/Outdoor (K) | |

| Operating Temperature | -40°C to +85°C |

| Storage Temperature | -40°C to +85°C |

| Installation Temperature (cable temp.) | -0°C to +60°C |

| Flame Retardancy | UL Listed Type OFNP (ANSI/NFPA 262) and FT6 (CSA C22.2 No. 232) |

| Impact Resistance | 1,000 impacts |

| Crush Resistance | 2,100 N/cm |

| Flex Resistance | 2,000 Cycles |

Note:Optical Cable Corporation reserves the right to Change This specifications without prior notification.

Download PDF