Description

For assistance, email CustomerService@americancableassemblies.com or call (413) 283-2515 (8AM - 5PM ET).

American Cable Assemblies takes pride in the creation of our Custom Pre-Terminated Fiber Optic Cable Assemblies, meticulously crafted in the USA with a distinguished legacy of 25+ years marked by unparalleled premium quality and reliability. As an ISO 9001 certified manufacturer, we uphold stringent quality control processes, ensuring excellence at every stage.

Experience the simplicity of our ordering process, coupled with the swiftest production and transit times in the industry. We provide continuous updates on your order status, delivering instant order confirmations, a ship date within 24 hours, and tracking information as soon as your custom assembly is dispatched.

Upon receiving your custom order, we meticulously construct the assembly to your precise specifications, utilizing premium components, including Corning® glass. Skilled technicians in the USA oversee the assembly process with rigorous quality control measures, presenting you with a fully tested product ready for immediate installation. Rest assured, your fiber assembly will not only arrive promptly but will also surpass your expectations. Our knowledgeable experts are available to assist you in selecting the ideal assembly for your specific application.

Tailored for various scenarios, our pre-terminated fiber optic assemblies are ideal for headend termination to a fiber backbone, terminating fiber rack systems, multi-floor deployments, and intra-building backbones. Additionally, our indoor plenum-rated jacket assemblies are suitable for all indoor installations, including plenum-rated spaces, meeting the low-smoke characteristics defined by the NFPA (National Fire Protection Agency).

American Cable Assemblies Micro-Distribution Excellence:- Tailored Craftsmanship: Your Pre-Terminated Micro-Distribution Assembly is uniquely crafted upon order, utilizing Corning® fiber and premium components tailored to your specifications. Each 12-strand grouped breakout is fortified with 2mm furcation tubing for ruggedization and protection during installation, complemented by sequential numerical labels for easy identification.

- Secure Connectivity: Buffer tubes are securely fastened to each 12-strand breakout kit using high-strength adhesive-type heat shrink tubing. The first main breakout occurs 12 inches from the main jacket, with 36" breakouts for each 12-strand group and a 6" stagger for enhanced flexibility.

- Connector Optimization: Connectors are staggered to minimize pulling basket size to approximately 1", ensuring efficient installation. Heat shrink tubing is strategically applied at transitions from buffer tubes to the cable jacket, each 12-strand inner cable to the breakout kit, where the basket meets the turn buckle (pull eye hook), and where the basket connects with the cable's jacket.

- Identification and Traceability: Each cable assembly end is equipped with a wrap-around label containing the cable part number and a unique serialized number. Pulling Eyes, if equipped, feature super-strong polyethylene mesh and a free-spinning buckle to eliminate cable twisting during the pull.

- Enhanced Flexibility: Boasts a smaller cable diameter and increased flexibility, providing versatility in various deployment scenarios.

- Ideal for High-Density Infrastructures: Tailored to meet the demands of high-density setups, ensuring efficient and reliable performance.

- Space-Efficient Design: Perfect for saving space in data racks, cabinets, and closets, maximizing storage and installation efficiency.

- Premium Material Construction: Crafted with the highest quality materials, meeting and surpassing exacting industry standards.

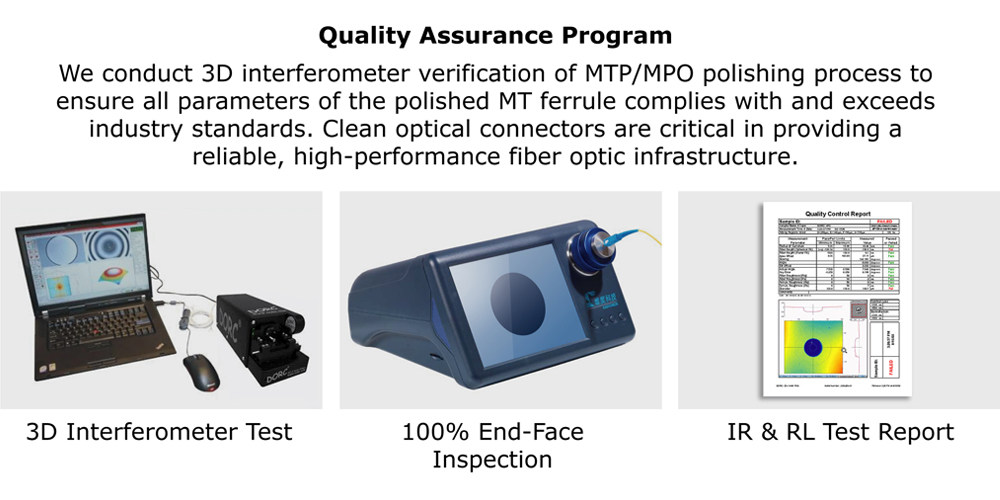

- Rigorous Testing: Thoroughly tested to meet or exceed EIA/TIA 568/GR-409-CORE standards, ensuring reliability and compliance.

- Tensile Strength Assurance: All aramid tensile strength members within sub-units guarantee durability and consistent performance.